JSWAY | 1990'dan beri Lider CNC Torna Üreticisi 2007

Swiss Type Cnc Lathe EXW FOB CIF - - JSWAY

Company Advantages

· The deft design of swiss type cnc lathe has attracted more and more customers.

· The product keeps operating smoothly throughout its lifetime.

· In Guangdong JSWAY CNC Machine Tool Co., Ltd. , process requirements of producing swiss type cnc lathe is very strict.

Produkta Priskribo

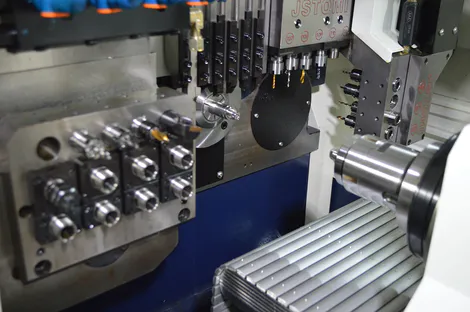

CNC Swiss Lathe A253 is a compact, high-precision machine for crafting metal and plastic components, ideal for custom and intricate parts. It comes ready to run with necessary software and accessories, features a small machine footprint, and allows for versatile machining. It<000000>#39;s suitable for small to medium-sized projects, offering accuracy and cost savings.

|  |

What makes a Swiss lathe different?

Swiss-type lathe machines are designed for making small, precise parts. The swiss type cnc automatic lathe is different from a conventional lathe in several ways.

First, swiss-type lathes have a smaller footprint and require less floor space than a conventional lathe. Second, swiss cnc lathes have a shorter bed length, which allows for more accurate machining of smaller parts. Third, swiss-type lathes are equipped with high-pressure coolant systems that enable the machining of difficult-to-cut materials. Finally, swiss-type lathes are equipped with live tooling, which allows for the machining of complex parts with multiple axes of rotation.

Swiss type lathes offer many advantages over conventional lathes and are an essential tool for any shop that specializes in the machining of small parts.

| Modelo Nr. | A253 | |

| Structural type | Horizontal tool type | |

| Operating System | FANUC or SYNTEC | |

| AXES | XYZ | |

| Rapid traverse rate (M/min) | X axis 24, others 30 | |

| Processing ability | The diameter of the bar held by the spindle (MM) | 5-25 |

| Maximum drilling diameter of spindle (MM) | 10 | |

| Maximum tapping diameter of spindle (M) | M8 | |

| The diameter of the bar held by the sub-spindle (MM) | N | |

| Maximum drilling diameter of sub-spindle (MM) | N | |

| Maximum tapping diameter of sub-spindle (M) | N | |

| Maximum drilling diameter of side milling power head (MM) | 10 | |

| Maximum tapping diameter of side milling power head (M) | M8 | |

| Spindle | Spindle power (KW) |

FANUC 3.7

SYNTEC 5.5 |

| Sub-spindle power (KW) |

FANUC 3.7

SYNTEC 5.5 | |

| Maximum spindle speed (RMP) | 6000 | |

| Spindle table | Spindle linkage movable guide bush stroke (MM) | 200 |

| Max movement | Without guide bush (optional, MM) | 290 |

| Tools | Quantity of turning tools (pieces) | 12x12MM,6 pieces |

| Side power tool (pieces) | ER20,5 pieces | |

| Spindle end face tool (pieces) | fixed tools ER16,6 pieces | |

| Sub-spindle end face tool (pieces) | N | |

| Sub-spindle side tool | N | |

| Total quantity of tools | 17 | |

| Maximum speed of power head (RPM) | 5500 | |

| Others | Size(LWH, approximate, MM) | 1900x1300x1740 |

| Weight (approximate, KG) | 2500 | |

| Optional configuration | Thermal compensation function | N |

| Automatic chip breaking function | N | |

What types of parts are typically produced on Swiss CNC lathes?

Swiss lathes are commonly used for producing small parts with complex geometries and tight tolerances, such as medical components, aerospace parts, and electronics. Some examples of applications include:

– Medical components, such as surgical instruments, implants, and prosthetics

– Aerospace parts, such as connectors, fittings, and valves

– Electronics components, such as connectors, pins, and sockets

– Automotive components, such as fuel injectors, valves, and connectors

– Precision watch parts, such as gears, screws, and pins

– Firearms components, such as triggers, barrels, and firing pins

– Hydraulic and pneumatic components, such as fittings and connectors

– Dental components, such as implants, abutments, and brackets

– Optical components, such as lenses, prisms, and mirrors

– Fasteners, such as screws, bolts, and nuts

5 Tips for Swiss Lathes

Running a Swiss-type isn’t the same as running a traditional lathe. Here are a few tips for Swiss CNC operators.

WHEN to Use a swiss type cnc automatic lathe?

It is best when parts have milled and turned features that require precision machining. Swiss CNC machining allows for many milled features (flats, hex edges, slots, left hand threading etc.) to be produced during the turning process without the need for multiple setups on additional equipment, providing greater production efficiencies with one process.

The rotary broaching process can be performed on these machines to cut standard or custom shapes into or onto a workpiece.

The ID centered rigid tapping or thread milling processes can be performed on the JSWAY CNC Swiss A253. You can also thread milling by using the live tools. There are multiple Swiss tooling companies that you can find a perfect tool for each application

When smaller, more complex parts are needed. Typically, those parts are non-standard parts and can not be sourced directly. Examples would be tamper proof bolts, special nuts, pins, custom mechanical parts, nozzle inserts, pick and place tips, antique jewelry and watch parts, gunsmithing parts, bullets, custom knives, fasteners, rc car and drone parts. JSWAY can reduce the lead times and offers more flexibility for the production volume compared to outsourcing the parts production to other companies

Most of the Swiss-type parts are less than 1” (25 mm) in diameter, with the majority being less than ¾” (19 mm) in diameter. You can make 1 milimeter diameter parts with less than 0.0002" tolerance. When the volumes are not too big to use the expensive and oversize Swiss cnc machine, JSWAY offers a lot of cost savings, lead time reduction and more flexibility. Please contact us for the precision level you can get!

Company Features

· Guangdong JSWAY CNC Machine Tool Co., Ltd. is a globally active player in the development, design, production, and distribution of high-quality swiss type cnc lathe.

· We have many clients nationwide and even worldwide. We undertake horizontal and vertical integration of the industry chain resources to create comprehensive competitive advantage and build a network of regional production and global marketing. We have our own design team with designers who know the ins and outs of the industry. We also have a QC team to guarantee the quality of products. Above all, we have professionals in every sector, such as R<000000>D, production, customer service, etc. to complete every project.

· We are struggling with the implementation of corporate sustainability strategies. We achieve cost savings on resources, materials, and waste management.

Produktaj Detaloj

Choose our swiss type cnc lathe for the following reasons.

Application of the Product

swiss type cnc lathe is one of the main products of JSTOMI. With wide application, our product can be applied to different industries and fields. And it is deeply loved and favored by customers.

JSTOMI insists on providing customers with CNC machining,CNC Lathe Machine,CNC Lathe Supplier of high quality and a one-stop solution that<000000>#39;s comprehensive and efficient.